Centrifugal Pump

OBWS

WESCO PUMP

APPLICATIONS AND USE

- I'st called a wesco pump which is a boiler feed water pump with OBWS type and largely divided a suction discharged casing, casing cover, impeller and bearing housing.

- Furthermore, the pump is never an axis impellent power, long life span and it's very good at small flux high head due to a high accuracy than others.

- Boiler feed water

- For transfer oil

- For assistance fire hydrant and spring cooler

- For all industries and general water supply

- For hillside transfer

- For special chemicals

STRUCTURE AND FEATURE

- It's very suitable for boiler water supply.

- It's easy to install and maintain with small size and a wider operation range than others.

- No need to use a jet pump as it can provide maximum 80°C degrees of water temperature with suction head for water supply.

- Need a high pressure and an inexpensive price with singlestage type.

- Do not set a slag in a pump when welding for plumbing. (Can affect impeller damages)

- Please operate it after put water in a pump without no-load operation. (Can cause a rotation inability)

- Do not operate it in a higher pressure than specification point. (Can cause a motor overload)

STANDARD SPECIFICATIONS

| Article | ||

|---|---|---|

| Discharge Capacity | 10~300ℓ/min | |

| Total Pump Head | 230m | |

| Design Pressure | 20kgf/㎠ | |

| Allowable Suction Press | 3kgf/㎠ | |

| Revolution Per minute | 1750rpm 60Hz | |

| Rotation Viewed From Driver | Clock Wise | |

| Temperature | 0~100℃ | |

| Suction Discharge Nozzles | Ratings | KS 10kg/㎠ |

| Facing | FF, RF | |

| Location | Side Suction, Top Discharge | |

| Shalt sealing system | Packing or Mechanical Seal | |

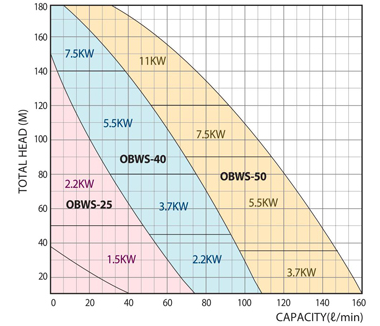

PERFORMANCE OVERVIEW

TECHNICAL DATA

| MODEL | BORE | SPECIFICATION | ||

|---|---|---|---|---|

| (SUC. X DIS.) | Q(ℓ/min) | H(m) | P(kw) | |

| OBWS-25 | 25X25 | 40 50 |

50 20 |

1.5 |

| 20 40 |

85 60 |

2.2 | ||

| OBWS-40 | 40X40 | 40 60 |

120 90 |

5.5 |

| 60 90 |

80 40 |

3.7 | ||

| OBWS-50 | 50X50 | 60 80 |

150 130 |

11 |

| 60 120 |

110 75 |

7.5 | ||

| 60 130 |

90 60 |

5.5 | ||

- Please apply it in case of GC200 for pump material butask us if it is SUS material.

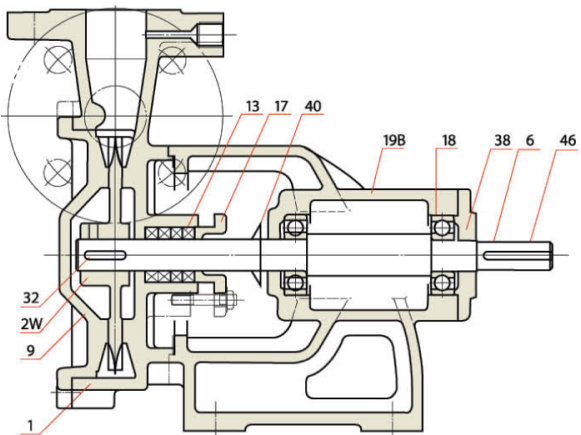

PUMP SECTIONAL VIEW

NAME OF PART

| No | NAME OF PART |

|---|---|

| 46 | COUPLING KEY |

| 40 | DEFLECTOR |

| 38 | BEARING COVER |

| 32 | IMPELLER KEY |

| 19B | BEARING HOUSING |

| 18 | BALL BEARING |

| 17 | PACKING GLAND |

| 13 | PACKING |

| 9 | END COVER |

| 6 | SHAFT |

| 2W | IMPELLER |

| 1 | CASING |

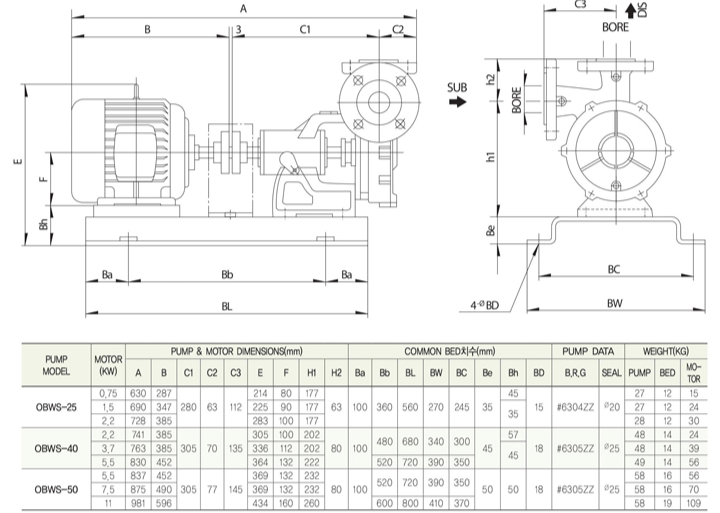

OUTLINE OF DIMENSION