Centrifugal Pump

OBSP

SELF PRIMING PUMP

APPLICATIONS AND USE

- Use in places which are needed a self priming pump and unavailable to install a foot valve and chemical plant.

- Review a material of pump in advance to avoid any chemical damages. (GC, SUS, ALLOY, HASTELLOY, CD4M)

- For Agriculture & Industry-Irrigation, Sprinkling, Drainage

- For wastewater treatment-General waste water, drainage for slurry.

- For chemical industry-Drainage and transfer waste chemicals

- For construction & civil engineering works-Construction water, drainage for septic tank and basement water.

- For marine-General water and drainage

- For an ultrasonic cleaner-Transfer of cleaner chemicals.

- And it can apply for all industrial settings variously.

STRUCTURE AND FEATURE

- No need a foot valve as it has a self priming pump structure which is attached own food valve in a pump.

- Easy disassembly of component and maintainance as it's a same disassembling way of general centrifugal pump.

- The pump has a long life span from a solidity of bearing housing.

- The pump has a long life span as the pump using 6300 of bearing categories.

- Type is a packing and m/seal.

- By a check valve in discharge line to go below the water flowing down the pipe in the water as the pump casing can be inhaled again.

- Applied a design method for sludge's easy transfer by using a impeller of semi-open type.

- More discharge rate and less electric power than others.

- Even if the impeller clogged from a casing full with garbage, it's designated to remove the garbage without pump disassembling.

- Bearing housing is a two way use for lubricant and grease.

- Even it's a basic coupling way, but it's possible to install in a narrow space as it designated with direct connection way as well.

STANDARD SPECIFICATIONS

| Article | |

|---|---|

| Max, capacity range | 250㎥/HR |

| Max pump head | 50M |

| Sealing method | GLAND PACKING, M/SEAL |

| Flange standard | 10kg/㎠(RF, FF) |

| Impeller structure | SEMI-OPEN TYPE |

| Revolutions per minute | 1750rpm, 3500rpm |

| Flange position | End Suction, Top Discharge |

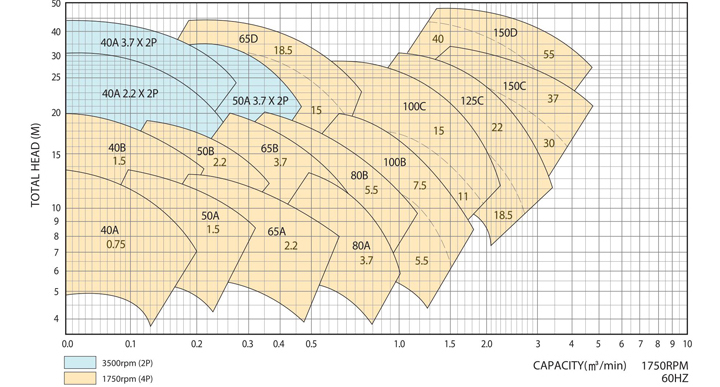

PERFORMANCE OVERVIEW

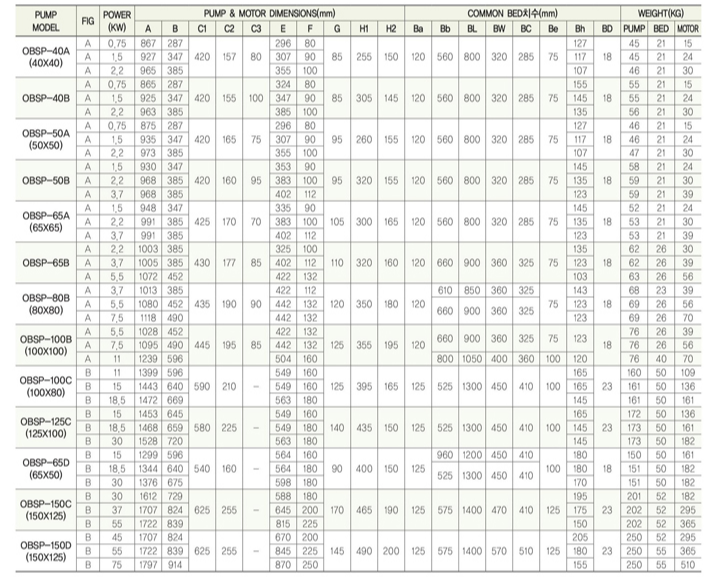

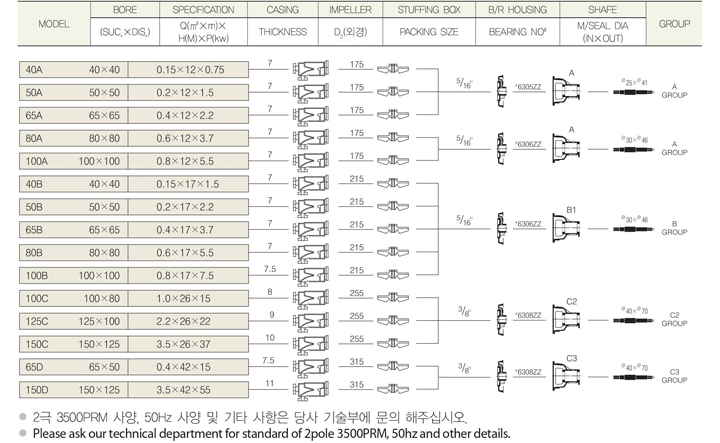

TECHNICAL DATA

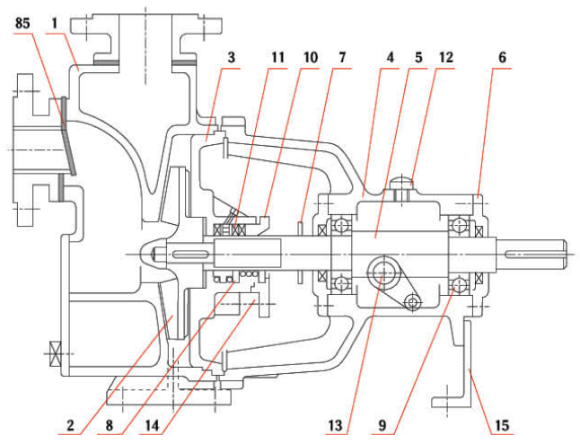

PUMP SECTIONAL VIEW

NAME OF PART

| No | NAME OF PART | Q'TY |

|---|---|---|

| 1 | CASING | 1 |

| 2 | IMPELLER | 1 |

| 3 | STUFFING BOX | 1 |

| 4 | BEARING HOUSING | 1 |

| 5 | SHAFT | 1 |

| 6 | BEARING COVER | 1 |

| 7 | DEFLECTOR | 1 |

| 8 | MECHANICAL SEAL | 1 |

| 9 | BALL BEARING | 1 |

| 10 | PACKING GLAND | 1 |

| 11 | PACKING | 3 |

| 12 | OIL CAP | 1 |

| 13 | OIL GAUGE | 1 |

| 14 | SEAL COVER | 1 |

| 15 | SUPPORT | 1 |

| 85 | NON RETURN VALVE | 1 |

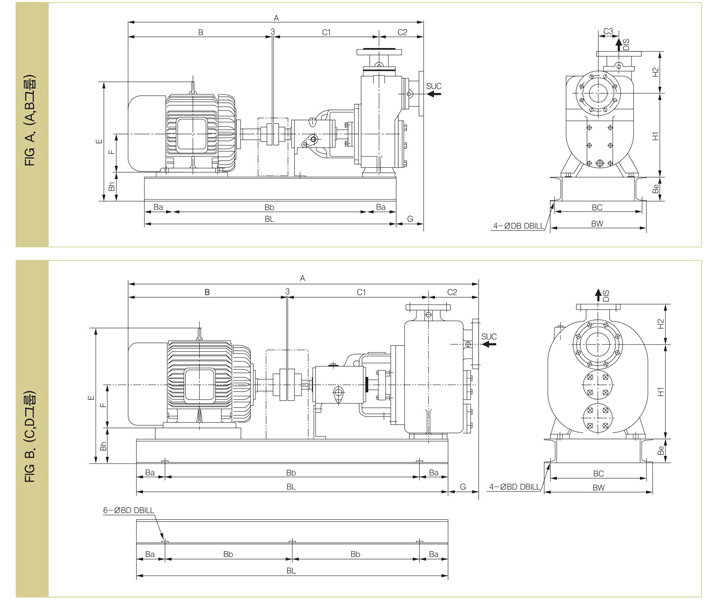

PUMP DIMENSIONS

OUT LINE OF DIMENSION