Centrifugal Pump

OBSH

Spurt Pump

Purpose

- Chemical industry: For transporting sludge and slurry

- Paper industry: For transporting treatment liquid, pulp liquid, and waste treatment

- Construction industry: For aggregate plants, sand plants, soil treatment, drainage treatment, septic tank cleaning

- Sludge: sewage sludge, raw sludge, excrement, livestock, leachate, sewage/wastewater

- Water supply: discharged water, concentrated sludge, surplus sludge, returned sludge, cleaning

- Others: For safe transporting of food, seaweed, leather, fruit, etc.

- Highly efficient transporting despite the presence of contaminants

Features

- Absolutely no clogging thanks to a non-clog impeller.

- V-Belt Type means specifications are variable, and operational efficiency is very high.

- Highly reliable due to its sturdy structure, and wear from abrasive solid substances is extremely low.

- Standardized components maximize compatibility.

- Easy to disassemble and assemble, which makes maintenance easier.

- Highest suction power among centrifugal sludge pumps (650~700mmHg).

Material

- Cast iron: GC, GCD

- Stainless steel: SSC13, SSC14, CD4MCU

- Aluminum: ALTA, ACTA

- High chrome: 20~27CIGC

- Lining: Soft and hard rubber, urethane, Teflon

- Other alloy steel and special series materials are manufactured upon consultation.

NAME OF PART

| No | NAME OF PART | MATERIAL |

|---|---|---|

| 16 | Oil Drain Plug | SM 45C |

| 15 | Bearing Nut | SM 45C |

| 14 | Support | GC 200 |

| 13 | Bearing Cover | GC 200 |

| 12 | V-Pulley | GC 200 |

| 11 | Self Priming Tank | GC 200 |

| 10 | Bearing Frame | GC 200 |

| 9 | Shaft | SM 45C |

| 8 | Thrust Bearing | BEARING STEEL |

| 7 | Adapter | GC 200 |

| 6 | Shaft Sleeve | STS 304 |

| 5 | Mechanical Seal | SC+SC |

| 4 | Radial Bearing | BEARING STEEL |

| 3 | Impeller | GC 200 |

| 2 | Casing Cover | GC 200 |

| 1 | Casing | GC 200 |

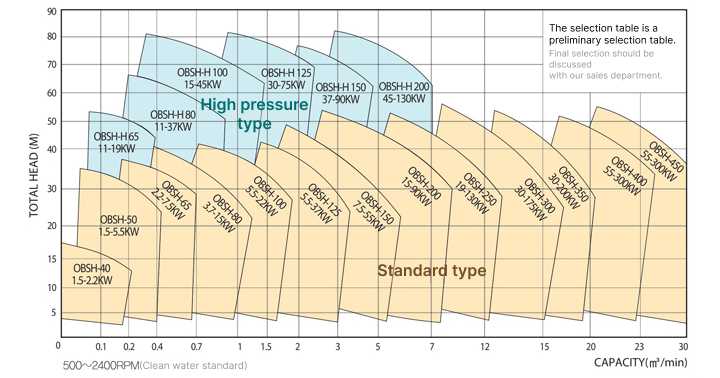

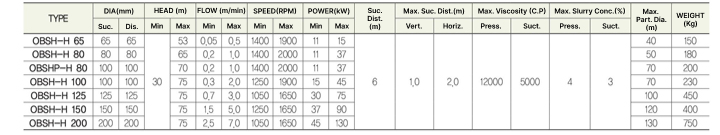

Selection Chart

Structure

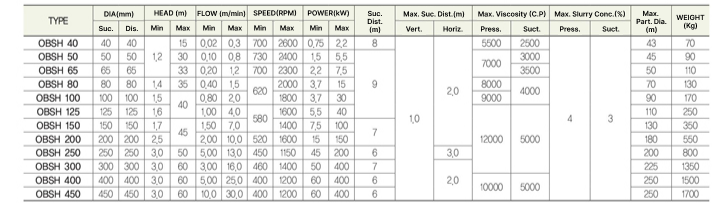

OBSH

OBSH-H

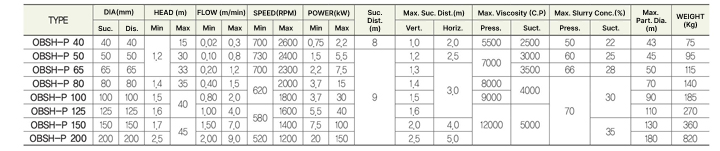

OBSH-P