Centrifugal Pump

OBIL

Inline Pump

Purpose

- Circulation of heating and cooling systems, replacement for horizontal volute pumps, pressurization, and liquid transfer in industrial and agricultural applications.

Features

- Guarantees high efficiency and reliability.

- Shaft seal or impeller can be replaced without removing the pump casing.

- Flow speed is gentle and noise level is low.

- Motor and impeller shaft are easy to inspect, maintain, and repair.

- Can be installed either vertically or horizontally (application varies depending on horsepower).

- Does not require a vibration isolation stand.

Standard Specifications

| Item | |

|---|---|

| Discharge | ~9㎥/min |

| Total Head | ~50m |

| Temperature | ~90℃ (90℃~140℃ is Special production) |

| Revolutions | 1450rpm, 1750rpm |

| Gauge | 40~200mm |

| Rotational Direction | Clockwise when viewed from the driving side |

| Flange | KS B 1511 10kg/㎠ |

Key Features of Built-in Inverter

- Individual inverter control function Controls the rotation speed with inverter. (can combine 3 inverters)

- Alarms An alarm is activated if the inverter, over current, waterlogging, high pressure, and low pressure sensor malfunctions.

- Select operating mode Set the operating mode according to the intended application. (heating and circulation)

- Save operating data Differential pressure control, temperature control, pressure control

- Powerful control functions Set the operating mode according to the intended application. (heating and circulation)

- Communication Inverter for each pump transmits and receives data.

- Automatic power failure recovery Once power is restored, it remembers the operating state and operates automatically.

- Emergency operation If the pressure transmitter fails, use the control panel to override and operate the system manually.

- Alternating operation Alternate operation according to the operation time setting of the main pump.

- Central surveillance Operating status is transmitted to the central control panel.

- Malfunction pump skip If a specific pump fails, the system automatically skips the pump and keeps the system operating.

- Self-diagnosis Increases reliability by monitoring failures and operating conditions around the clock.

- Waterlogger protection Prevents idling using a waterlogging sensor.

- Built-in MICOM Built-in 16-bit powerful CPU to execute faster commands.

TECHNICAL DATA

| Item | Casing | Impeller | Shaft | Sealing |

|---|---|---|---|---|

| Default Material | GC200 | GC200 | STS304 | Mechanical Seal |

| Optional Material | SSC13, SSC14, GCD450 | BC6, SSC13, SSC14 | STS316 |

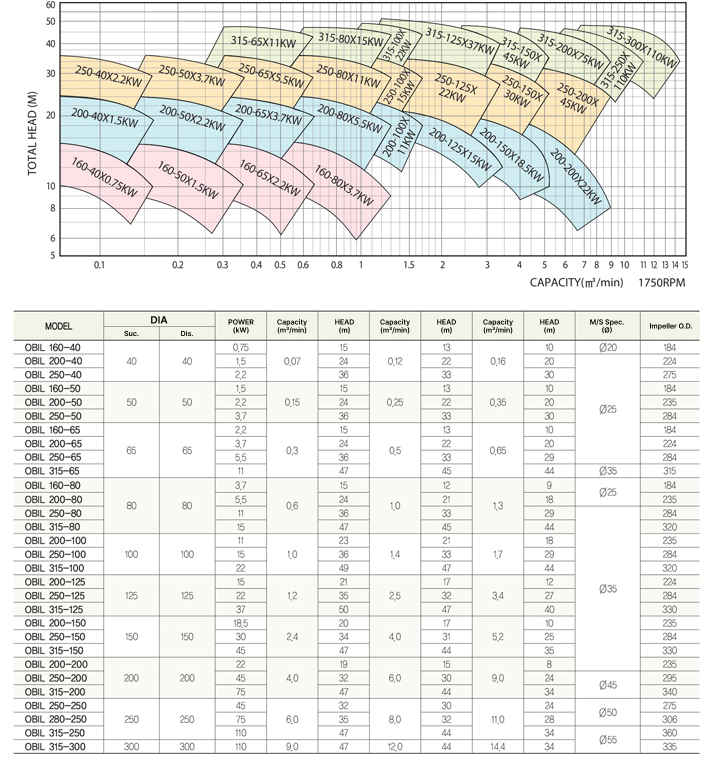

Selection Chart

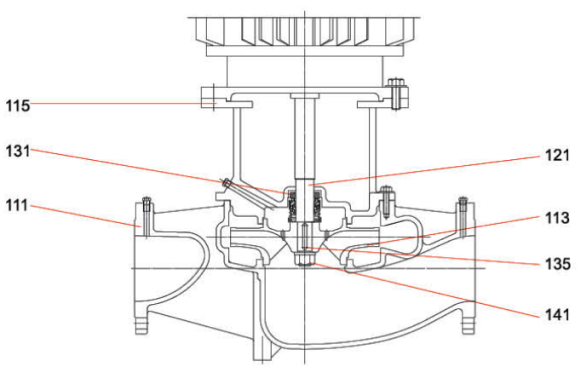

PUMP SECTIONAL VIEW

NAME OF PART

| No | NAME OF PART | MATERIAL |

|---|---|---|

| 111 | Casing | GC200 |

| 113 | Impeller | GC200 |

| 115 | Motor Bracket | GC200 |

| 121 | Shaft | STS304 |

| 131 | Mechanical Seal | SC/CARBON |

| 135 | Impeller Key | STS304 |

| 141 | Hexagon Nut | STS304 |

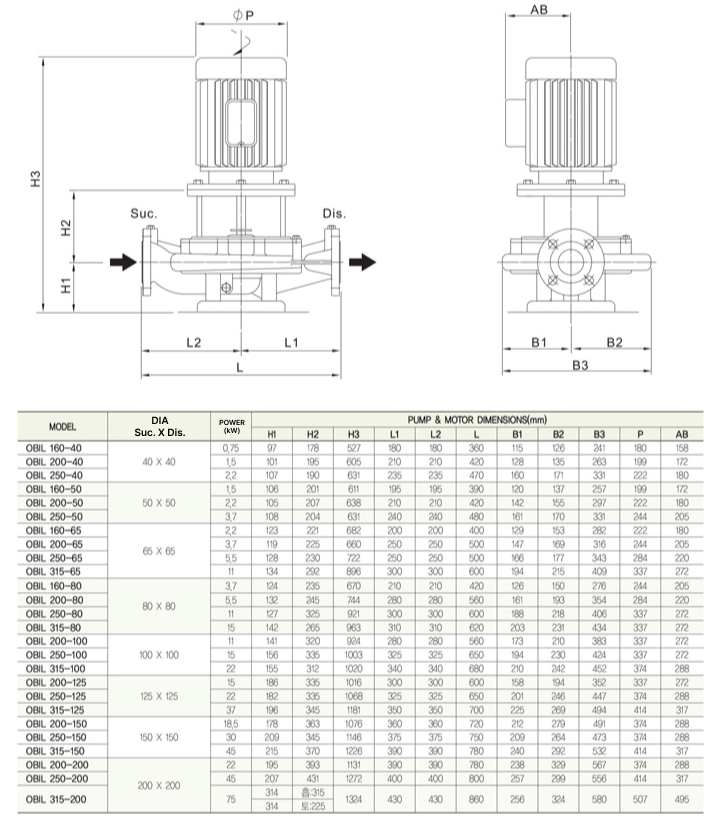

OUTLINE OF DIMENSION